Recently, the team led by Professor Yin Zhanhai, Director of Department of Orthopedics in the First Affiliated Hospital (FAH) of Xi’an Jiaotong University (XJTU), published important research results as an Research Article entitled “Electrohydrodynamic-Printed Dual-Triphase Microfibrous Scaffolds Reshaping the Lipidomic Profile for Enthesis Healing in a Rat Rotator Cuff Repair Model” in Small (IF: 13, JCR Q1). This study was completed by High-precision Biological 3D Printing Laboratory of Department of Orthopedics in FAH.

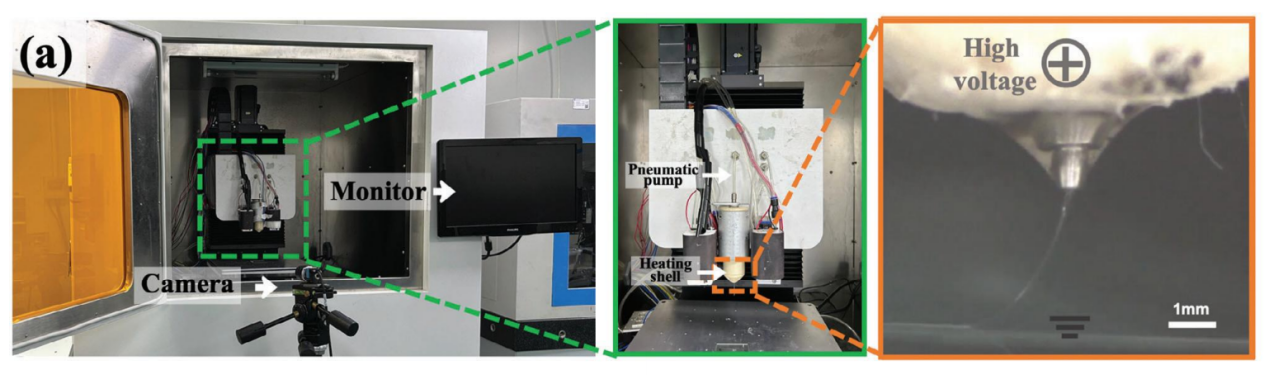

The laboratory, jointly established by the State Key Laboratory of Orthopedics and Mechanical Manufacturing System Engineering and Biological 3D Printing and Medical Restoration Engineering Center in FAH, focuses on the research in interdisciplinary fields of additive manufacturing, micro-nano manufacturing and bio-manufacturing, etc. The laboratory obtains multiple national invention patents for micro/nano 3D printing equipment, which can manufacture the world's leading tissue engineering scaffolds including cell printing and electrohydrodynamic printing. Based on these advanced technological platforms, Director Yin Zhanhai's team has successively published research results on cell-loaded hydrogel bio-ink micro-extrusion printing technology and solution-based electrohydrodynamic printing technology in Acta Biomaterialia (IF: 10.677) and International Journal of Extreme Manufacturing (IF: 16.1). Following these breakthroughs, the team further explored and successfully realized novel high-precision melting electrohydrodynamic (EHD) printing technology.

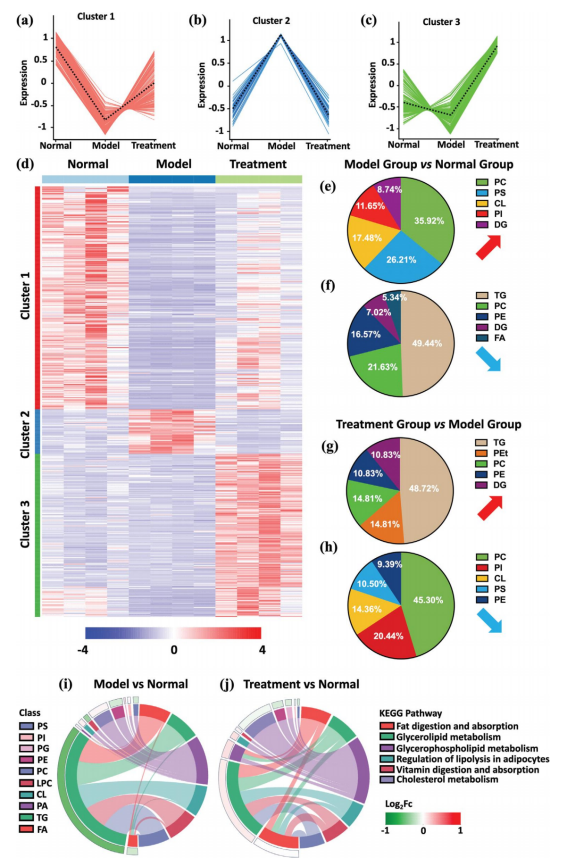

In this study, a dual-triphase microfibrous scaffold was developed by melting EHD printing technology. In the repair of rotator cuff injury, the scaffold not only optimizes the biomechanical properties, but also significantly reduces lipid infiltration and enhances tissue repair effect by precisely regulating the lipid microenvironment. The findings in this study demonstrate that this new scaffold can effectively guide the directional differentiation of stem cells, and has significant advantages in mechanical properties, structural stability and biocompatibility.

Through this innovative technology, Director Yin Zhanhai's team successfully improved the printing accuracy and structural stability of the scaffold, and accelerated further development of rotator cuff repair technology. This study not only provides more effective treatment for patients with rotator cuff injury, but also opens up a new direction for clinical application of tissue engineering and printing technology in the future.

Bai Lang, an assistant researcher from Department of Orthopedics in FAH, Ayiguli·Kasmu, a doctoral student from School of Mechanical Engineering of XJTU, and Wang Shuai, a graduate student from Department of Orthopedics in FAH are co-first authors. FAH is the first affiliation. Professor Yin Zhanhai, Director of Department of Orthopedics, and Professor He Jiankang, Deputy Director of School of Mechanical Engineering of XJTU are co-corresponding authors.